JWC Muffin Monster

JWC Environmental has successfully installed over 30 000 Monsters around the world in a wide range of municipal wastewater applications. The JWC Monster range is designed specifically for headworks, pump stations, pump protection, digester protection, centrifuge protection, sludge grinding, storm overflow and many other applications.

The Muffin Monster® grinders protect pumps and sludge dewatering equipment from clogging. They help prevent torn belts and damaged rollers in belt presses. These grinders facilitate a balanced and efficient centrifuge operation, and after dewatering, they ensure uniform particle size for easy handling and disposal.

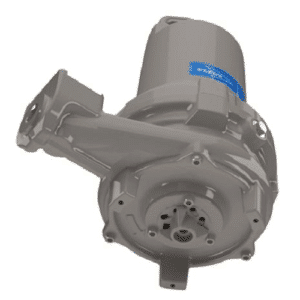

JWC inline Muffin Monsters are offered as the following models;

10K series Muffin Monster®

The 10K Series Muffin Monster is a compact grinder, tough on solids in sludge and sewage applications. It fits into areas with limited space requirements while still providing the necessary power for downstream protection. The 10K Series is an ideal, low-cost solution that goes beyond sludge grinding at resource recovery facilities, and fits perfectly into office buildings, apartment complexes, resorts, retail centers and package treatment plants.

30K series Muffin Monster®

Even more powerful and rugged, troublesome solids are now easier than ever to reduce with the Muffin Monster dual-shafted grinder. Its slow speed, high-torque design shreds tough solids that typically cause sewer problems. With over 35,000 installations, the proven capabilities of the Muffin Monster is legendary in providing solutions for the ever more stringent operational needs arising throughout the industry.

40K series Muffin Monster®

The 40K Series Muffin Monster excels in wet and dry grinding applications. It’s a powerful shredder for large sludge processing systems. It also serves in many industrial applications including fish and beef processing, petroleum, pulp and paper mills, chemical plants, and recycling plants. The proven capabilities of the Muffin Monster are now providing solutions for the ever more stringent operational needs arising throughout the industry.

- Capture, grind and remove more solids than alternative technologies.

- Cleaner, dewatered screenings.

- Minimize labor-intensive waste handling, reduce transport costs and pay less to landfill.

- Protect pumps and minimize costly downtime.

- Modular design installs easily without civil work.

- Monsters do not require enclosures or buildings

- Compact and efficient design

- Dual shafted grinder

- Lift stations

- Sludge lines

- Septage receiving stations

- Headworks screening reduction

- Prisons, Hospitals, Hotels